- Documentation

- Table of contents

- AKC

- Introduction

- Airframe Creation

- Technological Problems

- Experimental plant

- Building plant

- Conf. Development

- Aerodynamic Designing

- Algorithms of control

- Guidance & control

- Stand for training

- Training center

- Horizontal flight tests

- Crew on board

- Auto Landing complex

- Structure

- Payload bay

- Metallic material

- Non metallic material

- Non metallic material

- Cabin assembly

- Thermal designing

- Thermal protection

- Heat protection

- Quartz fibre

- Computer designing

- Gas's dynamic

- Strength

- Basic direction

- Tech. preparation

- Technical diagnostics

- Methods & means

- Radio nav. support

- Information & controls

- Control of onboard equ.

- Electric power dist.

- Electromagnetic

- Antennas installation

- Auxiliary power unit

- Hydraulic system

- Cabin

- Safety

- Air transportation

- Automatic landing

- Exp. working out

- Return to space

- SPIRAL

- Analysis of concept

- Horizontal take-off

- BOR-4 & BOR-5

- MAKS multipurpose

- MAKS-D

- Thermal design

- Gas & thermal design

- Wing deflection

- Flight performance

- Maks structure

- Metal materials

- Advanced non metallic

- Information provision

- Onboard starting comp.

- Onboard control comp.

- Control organization

- Aerospace systems

- Economic investigations

- Triplane aircraft

- Technical inventions

- Scientific potential

- Triumph and tragedy

- Birds of a Feather?

- TsAGI wind tunnel

- Bibliography

| -The Mriya is destroyed. |

| -Shipping of Buran-KS to Sotchi. |

| -Antonov is no more. |

| -Buran is now a museum. |

| -New pictures of the blogger Ralph Mirebs. |

BURAN Orbital

Spaceship Airframe

Creation

Basic Directions of Technology Development

at Creation of BURAN Orbital Spaceship

Podkolzin V.G., Chernousov V.N.

Some technological aspects of manufacturing BURAN Orbital Spaceship (Orbiter) are considered. The attention is mainly focused on technological features of airframe, cabin module and hydro-gas systems manufacturing.

Introduction

BURAN orbiter has a number of design and technological distinctive features in comparison with airplanes. The main of them are: availability of heat protection, high level requirements for cabin and hydro-gas systems module tightness, fuselage plasma-tightness in locations of payload bay doors (folds) connectors and wheel wells, and for undulation of metal airframe external contours.

At creation of BURAN Orbiter, the system of through design, production, maintenance and repair is applied. The system provides for the development of technological guidelines for designers with the purpose of maintenance of optimum units and systems design in view of analysis and synthesis of knowledge and experience in the field of design, materials, technologies, equipment and organization of production and management.

The requirements to manufacturability of BURAN Orbiter design have defined its technology and revealed its design and technological features and technical problems and tasks, which are subject to solution.

We shall consider a few directions of BURAN Orbiter production technology.

Airframe

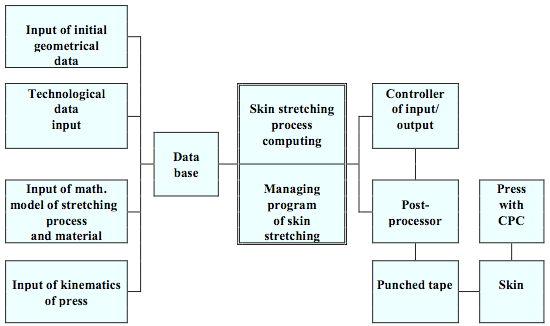

Implementation in BURAN of a great many parts of skin, made from aluminum alloys (such as D16ch) in artificialy aged state, as well as large overall dimensions, high requirements for accuracy of parts, their strength, reliability and service life have caused the necessity of the automated controlled forming processes development. In the period of BURAN creation, designed and automated controlled manufacturing process of skins forming by stretch-tension methods (Fig. 1) were introduced in cooperation with industrial research and high school institutes.

The system of computer-aided designing managing programs (MP) for forming skins of various shapes for application at stretch- tension presses with computer program control (CPC) was designed for these purposes. Mathematical models of the process permitting to determine the stressedly-deformed state of material at forming, geometry of the part surface, material technological capabilities and press actuators motion are applied in the system.

Material technological capabilities are restrained by critical deformations (εcr), which excess results in intensified growth of grain at the subsequent heat treatment. Therefore, the knowledge of εcr for every definite delivery of material permits to optimize the forming regulation. It is established, that the larger is the grain (>> 500…1000 microns), the worse are technological and service properties of the parts’ material.

|

|

Figure 1. Block diagram of computer-aided technology development of skin stretching |

The value of εcr essentially depends on technological heredity of metallurgic production, i.e. on chemical composition, annealing temperature and time, cooling and rate of stretch flattening deformation. Comparative analysis of many batches of sheet intermediate product of D16ch alloy has allowed to make a conclusion that when manganese (Mn) content is closer to the lower level of 0.3 … 0.4%, εcr is 4 … 6%, and at Mn content is over 0.6% it exceeds 8%. It is explained by that manganese is the basic anti-crystallizer generating hardly-deformed compounds, which hinder re-crystallization. Since no εcr estimation is made at metallurgical works and its value is not indicated in a certificate, the express-method of material εcr estimation has been designed. Knowing the true value of εcr and using computer-aided processes the strict observance of forming process mode at exclusion of big crystals creation can be ensured.

The accuracy of skins depends on the accuracy, strength and rigidity of stretching punches. Hollow cast (of aluminum alloys) punches of modular structure, which surfaces are treated under the program on three or five-coordinate machine tools, comply with these conditions. Strength calculation and rigidity of punches, and their technological designing are implement with usage of computer-aided system of stretching equipment designing.

Mastering the controlled manufacturing processes was accomplished at manufacturing skins of various shapes (frontal skins, skins of double curvature, hatches, etc.) and of maximum width of 6 mm and of sizes of 2000 × 6000 mm.

Controlled manufacturing processes of wrap-stretching performed on presses with CPC were used for forming honeycombed panels of rudder and air brake.

More than 800 kg of deeply-corrugated panels of D16ch and 1201 alloys were used in BURAN Orbiter construction as walls of load-bearing frames of fuselage and wing ribs first applied in artificially aged state (T1), characterized by high load ratio and manufactured according to the new technology. The specific features of the developed technology lie in the arrangement of conditions for creation of grooves with small residual deformations. This permits to receive parts practically without thinning the blank material.

The process consists of consequent bending of open grooves and intake of material from the end section of the open groove to the technological groove-pinch.

The process is implemented at forming parts of the different sizes and thickness (maximum sizes of 1.2 × 1200 × 1900 mm) with a universal fixing and on universal equipment.

The designed way of forming panels with deep grooves, the applied modes, as well as method of calculation and equipment have ensured new design shapes of parts. This parts are of minimum residual deformations, of practically unlimited sizes, displaying good indices of contraction, plane displacement and bending parameters of functioning in units and ensuring high design strength and service life.

The technology of casting thin-walled castings of high-strength steels with wall thickness up to 1.0 mm, surface smoothness of the casting Rz = 20, without mechanical finishing allowance, accuracy of sizes of +0.15…0.6 mm was developed.

The distinctive feature of the technology consists in that the steel melting is accomplished in a controlled atmosphere. As to filling up, it is made into shell molds, placed in controlled temperature field, without reference filling material. Melting is carried out in a high-speed flow of hot air or at intensified saturated steam pressure. The cast scouring off ceramics is made without abrasive surface treatment.

A great many of BURAN’s parts of bracket type of ZhS6 alloy were manufactured under the designed technology and have passed all tests with positive results.

The most laborious and continuous manufacturing process is the heat-protection laying. The cycle of its laying had extended the cycle of BURAN Orbiter creation; it was the final stage and could not be combined neither with mounting, nor with tests.

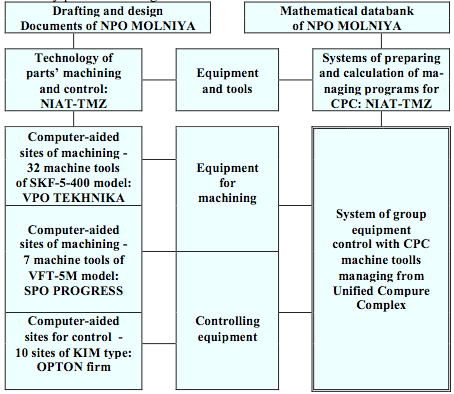

Heat-protective elements of BURAN airframe, depending on their purpose, differed by design and materials. For the TPS (Thermal Protection System) tiles a heat-protective material, made of quartz fiber with erosion-resistant and hydrophobic coating functioning at temperature up to 1250oС, was applied. The tiles were produced from blocks by mechanical machining. An automated line, designed at NIAT institue and manufactured at ELEKTROTEKHNIKA production and designing association (Rzhev), was implemented at NPO TEKHNOLOGIA for production of blocks. Special purpose SKF-5-400 and SKF-5-300 machine tools with CPC were created at VPO TEKHNIKA, and VFT-5M – at SPO PROGRESS for the TPS tiles machining. The machine tools were five-coordinate, oilfree version with metallic chip suction and controlled from a unified SM-4 computer.

In Fig. 2, the main components of the TPS tiles’ materials machining technology are displayed.

Five-coordinate chambers with ‘Vector’ system of KShP-1 type were designed at NIAT and manufactured at RPKO ELEKTRO-TEKHNIKA for laying coating on the tiles. A tunnel kiln of TSP-2 type was designed and manufactured at RPKO ELEKTRO-TEKHNIKA for hydrophobic coating baking.

At TUSHINSKY Machine Building Plant (TMZ) computer-aided system for control on technological process was created. This system is intended for controlling the processes of machining, test and measuring equipment and storage rooms, and storing information on measurement of actual metal surface and correcting the program of contact tile’s surface processing.

The parts, most exposed to thermal impact (up to 1600oС), were made of composite carbon-carbon material, designed at GRAFIT institue, VIAM institute and NPO MOLNIYA. This material has been named as ‘GRAVIMOL’. The technology of parts manufacturing of this material was designed in NIAT, VIAM and GRAPHITE institutes and implemented at the Moscow Electrode Plant. Moulds, monitoring equipment for layout (calculation) and piercing, assembly and stockpile, totally – more than 500 units were designed and implemented at NPO MOLNIYA. The values of shrinkages were not clear for this new poorly studied material both at low and at high-temperature limits. Due to good interaction of experts of SOYUZUGLEROD and NIAT institutes, deviations of parts by shape were remedied in the process of production. Many institutes and industrial plants have participated in application of the GRAVIMOL materil into BURAN’s parts (fuselage and wing units).

The following items were manufactured and implemented:

- equipment of 9 models (of 9 types);

- about 700 units of special auxiliaries;

- 12 items of special purpose cutting tools, including diamond tools.

The parts, made from GRAVIMOL material, are displayed in Fig. 3 and 4, to give an example.

For manufacturing payload bay doors (PLBD), NOVOSIBIRSK Aircraft Production Plant named after V.P. Chkalov, designed and manufactured an unique equipment for forming and assembly. NPO TEKHNOLOGIA at the first in domestic practice had formed panels of doors from composite carbon fiber reinforced plastic (KMU material), and VORONEZH Industrial Association had manufactured the doors of radiation heat exchanger (RHE).

These units passed development under the conditions both at manufacturing plants, and TMZ head assembly plant. NIAT together with NPO MOLNIYA has designed unique benches for PLBD operation development in view of operational loads. Technology of ultrasonic control with application of the leakage detectors, made by Electronic Detectors Corporation (Belgium), was designed for control of local fuselage non-tightness in PLBD and SNSh units.

The technology permits to detect leakages in all types of doors, gates and hatches seals, at that many joints can be tested from exterior of Orbiter without dismantling the tiles’ heat-protection material. Much work was carried out to create the technology and means ensuring the system of onboard measurements (SOM) sensors attaching and mounting.

|

|

Figure 2. The TPS tiles’ material machanical machining process |

This process was integrated with providing the required temperature and pressure at gluing, and glues and priming selection, as well as designing and manufacturing special-purpose equipment and facilities for maintenance of polymerization temperature of glue directly on the article. As a whole for the SOM system 15 manufacturing processes were designed, certificated and implemented.

Cabin

The main problems at manufacturing high-strength and tight module of cabin were as follows:

- development of manufacturing processes for bulky parts from 1201 aluminum alloy with small residual deformations;

- the new machine-tool complex’s creation, CPC of UPSF-2 model encluded, for machining, assembly and welding a tight habitable cabin, ensuring obtaining a welded joint, equal by strength to its original material.

With the purpose of considerable reduction of residual deformation during machining of parts from 1201 alloy 1201, a scheme of deformation-free technology with sequential processing for two opposite sides of parts relatively to the symmetry axis was applied. A technology of achievement parts’ thickness, equal or smaller than 1.8 mm, was designed.

The specificity of manufacturing parts of 1201 alloy is that at material aging its linear dimensions are incremented by 0.1%. After aging, no straightening of parts was admitted, since in aged condition the deformation should not exceed 0.6%.

The distinctive feature of manufacturing process of cabin module is that its machining, assembly and welding are conducted completely on one work place with provision of unity of bases and rigidity of the MGTP system (machine-gadget-tool-part). To ensure these requirements, NIAT has designed, and SAVELOVSKOE Industrial Association (SPO PROGRESS) and RPKO ELECTROTEKH-NIKA have made a five-coordinate system with the CPC of UPSF-2 type. The systems of UPSF-2 type are in essence flexible industrial modules and can be applied for sectoring and measurement of a surface, local heat treatment and chemical milling, winding and bulk lattice of composite designs, control of air-tightness and so on. The appropriate heads are installed for performance of the mentioned operations on the console.

Devices for automatic in-welding of internal load-bearing structure units and elements of attachment were designed and implemented at the Institute of Welding named after Paton from Ukrainian Academy of Sciences together with NIAT. The systems of such type are not applied in foreign practice.

The problem of ensuring the air-tightness of the BURAN Orbiter’s cabin was solved at a qualitatively new level with allowance for necessity of measuring smalls leakages and obtaining quantitative information on this parameter. In this connection, different design and technological measures were applied to provide the cabin air-tightness.

An automated monitoring system, using a compensating and differential method of control with pressure variation rate sensitivity of 1.3·10-2 Pa/sec, was designed at NIAT, NPO MOLNIYA and TsNIIRTK institue for estimation of the total leakage in cabins at the stage of pressure tests.

A mass-spectrometric method with application of evacuated chamber of TVU-1000 type, permitting to detect cabin nonhermeticity of 1.3·10-5 W, was designed at NIAT, NPO MOLNIYA and TMZ for detection of the total leakage from the cabin after its final assembly-welding.

For the first time, the method of ‘probe’ with crio-adsorption evacuation of mass-spectrometric leakage indicator was applied for detection of a local leakage from cabins of 6.5·10-8 W. The new methods and means of air-tightness control are described in details in a separate article of this collection.

Hydrogas system

The service life and reliability of BURAN Orbiter are in many respects determined by the quality of manufacturing, mounting, washing, air-tightness control and hydrogas systems development.

Together with NIITM, NIAT has developed and completed the tests of essentially new technology of manufacturing the elements of steel and aluminum pipeline with wall thickness of 0.5 mm.

The process of obtaining bimetallic (steel+aluminum) adapters for connection of pipelines, made of different metals, was implemented at TMZ plant. The complex of manufacturing processes was designed for making a one-piece (full welded) pipeline of high service life index, mounting for pipelines with two-barrier seal, ensuring the minimum assembly stresses.

The method of radioactive isotopes (RAI) with application of Krypton-85 radio-nuclide with sensitivity of 10-8 cm3/sec was designed by NIAT, SMNU-113 (Volgograd) and NPO MOLNIYA for the control of air-tightness of hydraulic units and systems charged with working fluid.

The complex of production equipment, including SOP-100M, SOP-400, STZ-100M and OTs-100M stands, was created for technological development of hydraulic systems of BURAN Orbiter. The optimum filtration scheme of working fluid mechanical inclusions was applied on the basis of selection of filters, samplers, and their allocation in the united hydraulic system. The problem of regulation of production equipment power was simultaneously solved at washing and development of Orbiter airframe hydraulic systems functioning.

As a result of BURAN spaceship production, technological maintenance, more than 500 scientific-research and experimental-design developments were executed, including:

- Orbiter’s manufacturability was completed at all production phases with issue of 1,560 notes on design documentation;

- directive technological documents for all kinds of production were designed, including 2,100 pieces of directive manufacturing processes, 340 pieces of requirement specifications on the equipment and fixing, and 38 pieces of the branch engineering specifications;

- program and software on the technology of manufacturing heat-protection of the Orbiter were designed;

- measures on beginning the Orbiter’s mass production at plants of the branch were designed, which allowed to increase the automation of works and to lower their labor intensity;

- complex technical and economic analysis and calculation of costs of development, manufacturing and tests of the article, including calculation of labor intensity and metal consumption of the article was carried out;

- scheme of cooperation for manufacturing the Orbiter at the plants of the branch, and calculation of production volumes of Orbiter were developed;

- initial technological materials for designing new departments and workshops for production of the Orbiter were designed;

- an authorized supervision on compliance with the requirements of directive technological materials, indicated in the drafting-design documentation, and working technology of manufacturing plants was carried out.

The first flight of BURAN orbiter confirmed the excellence of the technology of its production.

Conclusions

1. The results of works on technological provision fot BURAN spaceship creation increased a scientific and technological level of flight vehicles’ production and ensured a set of operatioanal and technical features.

2. The new scientific directions of know-how were developed, including: heat protection manufacturing and mounting; one-piece hermetic cabin (of long life time) assembly and welding from high-strength heat-strengthened aluminum alloy; air-tightness control for airframe’s elements and systems of onboard equipment with the use of highly sensitive methods, etc.

3. 130 units of new advanced equipment, permitting to raise the level of manufacturing processes’ automation, were designed.

4. Program software for different technologies, including manufacturing and mounting of the heat protection, was designed.

5. Wide-scale implantation of an authorized supervision on compliance with the requirements of directive technological materials and drafting-design documentation and working technology at manufacturing plants promoted provision for the high quality of BURAN spaceship.

The major part of production technology of BURAN spaceship is protected by copyright certificates and is recommended for broad implementation into the national economy and for sale abroad.