- Documentation

- Table of contents

- AKC

- Introduction

- Airframe Creation

- Technological Problems

- Experimental plant

- Building plant

- Conf. Development

- Aerodynamic Designing

- Algorithms of control

- Guidance & control

- Stand for training

- Training center

- Horizontal flight tests

- Crew on board

- Auto Landing complex

- Structure

- Payload bay

- Metallic material

- Non metallic material

- Non metallic material

- Cabin assembly

- Thermal designing

- Thermal protection

- Heat protection

- Quartz fibre

- Computer designing

- Gas's dynamic

- Strength

- Basic direction

- Tech. preparation

- Technical diagnostics

- Methods & means

- Radio nav. support

- Information & controls

- Control of onboard equ.

- Electric power dist.

- Electromagnetic

- Antennas installation

- Auxiliary power unit

- Hydraulic system

- Cabin

- Safety

- Air transportation

- Automatic landing

- Exp. working out

- Return to space

- SPIRAL

- Analysis of concept

- Horizontal take-off

- BOR-4 & BOR-5

- MAKS multipurpose

- MAKS-D

- Thermal design

- Gas & thermal design

- Wing deflection

- Flight performance

- Maks structure

- Metal materials

- Advanced non metallic

- Information provision

- Onboard starting comp.

- Onboard control comp.

- Control organization

- Aerospace systems

- Economic investigations

- Triplane aircraft

- Technical inventions

- Scientific potential

- Triumph and tragedy

- Birds of a Feather?

- TsAGI wind tunnel

- Bibliography

| -The Mriya is destroyed. |

| -Shipping of Buran-KS to Sotchi. |

| -Antonov is no more. |

| -Buran is now a museum. |

| -New pictures of the blogger Ralph Mirebs. |

From SPIRAL to MAKS

The MAKS Onboard Starting Complex

Dr. Mushkarev Yu.G.

The paper gives a brief information about the Onboard Starting Complex placed on the AN-225 Carrier-Plane of the Multipurpose Aerospace System (MAKS). Main principles laid in the project and characteristics of the Onboard Starting Complex are discussed.

The injection of any artificial objects into an orbit is performed from an airdrome appearing to be complex enterprise with highly developed infrastructure, complicated engineering structures and communication network. Each launch is preceded by long-term, intensive and laborious works of high number of specialists in different areas of knowledge in many cities and settlements of the former USSR.

When the MAKS reusable aerospace system was in development, engineers from NPO MOLNIYA faced with non-trivial problems. One of these problems was to create ‘flying Baikonur’. In other words, the problem to develop and place on a board of carrier-plane starting complex, which is to provide execution of all actions, required for the orbital object’s preparation and start in the same way as from launching site, but considering operational features in flight conditions.

The MAKS on-board starting complex development requires to solve complicated scientific, technical, technological and organizational problems considering intensive co-operation of different enterprises:

1. Designing and production of the carrier- plane with given characteristics concerned lift capacity, flight altitude and range. This plane should have capabilities to place equipment and flying crew in on-board compartments, to provide their functioning and acceptable safety. The plane was designed and manufactured by ANTK named after O.K. Antonov (Kiev) and was called AN-225 MRIYA’.

2. Determination of operational and technical characteristics of the objects, intended for injection into an orbit from carrier-plane, and these objects’ development.

3. Analysis of tasks, solved by the on-board starting complex, its structure development, mass-energy performance calculation, to optimize the distribution of informational streams between carrier-plane (CP), on-board starting complex (OSC) and the MAKS orbital plane (OP).

4. The functions’ distribution between navigational-piloting complex of the carrier- plane and pre-launch preparation automated control system, information displaying systems and control systems of the carrier-plane and on-board starting complex.

5. Conception development for a ‘CP+OSC+OP crew’ model.

6. Determination of functional loads on OSC crew members considering a necessity to take crucial decision for launch and launch cancellation.

The on-board starting complex is used for the following purposes:

- pre-flight complex preparation;

- system control within joint flight to the start-up region;

- pre-flight payload (PL) preparation and its launch in starting point;

- actions execution at launch cancellation in abnormal situations;

- on-board system control when returns to the basing airdrome at launch cancellation;

- OSC equipment functioning maintenance;

- system power maintenance, including equipment placed on the on-board starting complex and payload;

- post-flight OSC system check-up;

- service condition maintenance for OSC flight crew.

During development of the on-board starting complex the following features were considered:

- up-to-date component application to achieve the best productivity, reliability, dimensions and power consumption;

- reconfiguration capability and functional redundancy to achieve high-level vitality;

- common external storage device application when storing data concerned onboard digital computer functioning, including information about bugs, failures and redundancy transfers;

- multiplexing principle application for information transfer to minimize inter-system connections;

- hardware redundancy application, majoring the equipment used in the OSC to achieve the best reliability and fault tolerance;

- block reservation of equipment used in the OSC, including communication lines;

- build-up control system application;

- application of wide experience gained during the BURAN designing, production and flights.

The major problems lie in ergonomic design when ‘OSC crew - OP crew’ conception model is created and polished.

The majority control actions by OSC systems are performed in autonomous mode. The operators are responsible for controlling all signals passed and control commands execution. However, the operators can and must directly execute a part of functions for on-board system controlling.

The list of situations determining when the operator can execute direct controlling, actions order, automatic-to-automated or automatic-to-manual and otherwise transfer methods with consideration of regular control methods is defined accurately during test bed simulation.

The system control is performed in three different modes:

- automatic – without operator interference in control process but with providing information about on-board systems status on information display system in volume required for right estimation of current situation by the operators;

- automated – dialog (data input, settings correction, control mode choosing and other) using multifunctional control means;

- manual – dialog mode control, system and process control with command passage and execution control through multiplex information channel and direct connections from control console.

The operators of the on-board starting complex are responsible for execution of the following tasks:

- participation in flight task input and correction, current system status control;

- settings input and correction;

- communication with the orbital stage crew and the carrier-plane crew as well as communication with ground guidance and control complex;

- commands and signals passage control;

- rapid analysis of control results concerned functioning of the OSC equipment;

- panoramic TV control of the MAKS second stage at joint flight leg with the carrier-plane and separation leg;

- control in automated and manual modes;

- parameters control;

- OP crew status control;

- abnormal situations detection and settlement;

- control mode selection for OSC systems;

- conducting of post-launch actions and actions at launch cancellation;

- report issue.

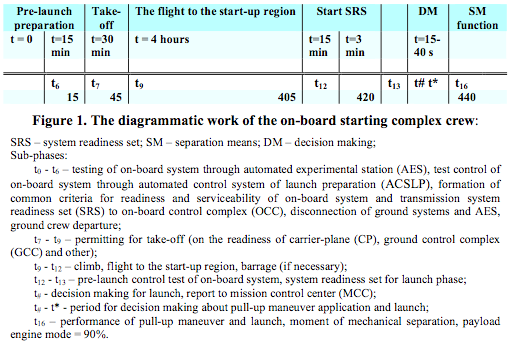

The order of task solutions is determined by diagrammatic work, which considers procedure time expanses and psycho-physiological abilities of the operators (Figure 1).

An analysis of tasks executed by crew of the on-board starting complex obviously shows that the major problems are to find out required number of the operators and to organize their activities and interactions. At that it is obligatory to minimize their number on conditions that they execute all their functions without any failure. The study performed by NPO MOLNIYA results in a preliminary conclusion about minimum two members of the on-board starting complex crew.

|

The on-board starting complex (OSC) is placed inside An-225 “MRIYA” carrier plane fuselage and guarantees pre-launch preparation and payload (PL) launch as well as action performance at launch cancellation in abnormal situations. As a payload a complex of equipment and units placed on An-225 suspension brackets is considered. It includes external fuel tank, orbital manned plane, orbital unmanned stage, experimental plane-demonstrator and other.

The on-board starting complex (OSC) consists of:

- automated control system for launch preparation and launch (ACSLPL);

- OSC information display system (IDS);

- power supply system (PSS);

- TV guidance and scanning system (TGSS);

- separation system (SS);

- air-hydraulic system of main propulsion unit (AHS MPU);

- air thermostatting system (ATS);

- liquid thermostating system (LTC);

- explosion and fire protection system (EFPS, in AHS);

- on-board telemetry measuring system (OTMS).

ACSLPL is designed for automated control of pre-launch and pre-flight preparations of PL on each preparation and flight phases, including launch preparation and launch, itself.

ACSLPL resolves the following tasks:

- control test and system preparation;

- control program execution for launch preparation and launch on each phases of pre-start preparation;

- information documentation on the results of pre-start preparation (PSP), including OSC operators’ actions;

- flight purpose input;

- delivery of information to information display system (IDS) and system control from IDS OSC.

ACSLPL consists of:

- on-board digital computer (ODC);

- external storage device (ESD);

- multiplex information communication channel (MICC);

- information documentation device (IDD);

- multiplex channel extender (РМК);

- software loading device (SLD);

- system software (ПО), including operating system, testing maintenance program, control test program, program for information documentation;

- special software, including software for pre-start preparation (PSP) maintenance, OS OSC status determination, launch preparation and launch, interaction with on-board control complex (OCC) of payload (PL).

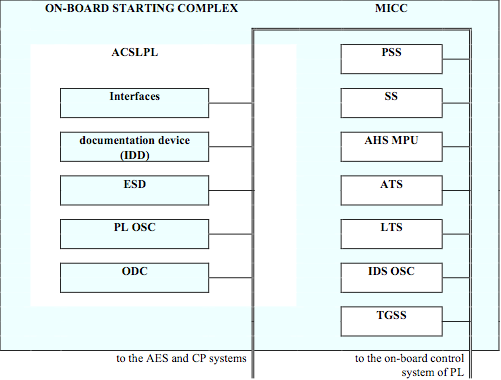

Data communication of ODC ACSLPL is performed through multiplex data communication channel with OCS, AES and PL systems in accordance with GOST 26 765.52-87 standard (see.figure 2).

Data processing from control devices of on-board system supposes determination of efficiency of all PL and OSC systems by means of parameters’ scanning and formation of common status characteristics shown to the operators and stored in documentation system.

On-board digital computer (ODC) is used for the following tasks:

- to calculate required settings for information processing from control devices of on-board system during pre-launch period;

- status analysis and control of OSC devices;

- information streams distribution between systems, external storage device and other.

Information exchange between ODC of ACSLPL and OSC of PL is performed by means of software information streams control with time division and three reserve data communication channels. The aim of pre-launch preparation is to turn on on-board systems and units and to transfer them into start readiness mode corresponds to the moment of separation of PL and CP.

During mode selections and following equipment exploiting technical state control procedures of software and hardware complex are executed.

The structure of pre-launch preparation of PL and OSC on-board equipment in aerospace complex performed by hardware and software facilities of AES and ACSLPL supposes consequent execution of the following steps:

- earth preparation;

- technical state control of PL and OSC on-board systems during the flight to the start-up region;

- PL preparation directly before launch.

The preparation phase includes turning-on, entrance on mode and testing of on-board systems of on-board control system of PL and OSC. Initial starting of on-board systems is executed by ground automated experimental station (AES). After entrance on mode a control is transferred and AES passes to the “scanning” mode.

|

|

Figure 2. Structural-functional scheme of the on-board starting complex (OSC) |

During the functioning ACSLPL transmits command to carry out testing of on-board systems of OSC and received ready signal from on-board systems it forms common criteria for complex readiness and serviceability to perform tasks and then transmits command to start motion.

When flying to the start-up region or inspecting ACSLPL manages OSC and constantly controls systems’ technical state.

At starting phase ACSLPL performs final check-up and entrance on mode systems of PL and OSC which are used in injection phase (separation system (SS), main propulsion unit (MPU) and other). At this phase an on-board system control are transferred from ACSLPL directly to on-board control system of PL.

After launch ACSLPL continues controlling on-board systems of OSC (turning-off of several on-board systems of OSC not reqired for carrier plane return to the basing airdrome. IDS of OSC performs following tasks:

- display of information concerned navigation and on-board systems’ status for OSC crew members;

- transmission of control actions to the on-board systems. Display system consists of: electronic indication facilities (EIF), including full-color screen indicators and multi-mode control consoles;

- imagery blocks;

- electronic dataware blocks;

- functional control consoles for OSC systems;

- speech synthesizer;

- verbal input device;

- computation system;

- cables.

Power supply and distribution system is used for power supply of OSC an PL equipment.

Power supply and distribution system consists of:

- storage batteries;

- distribution power devices;

- control and warning devices, controllers;

- cable system;

- airdrome power supply plug;

- currency control system.

Power supply system generates electricity of following types:

- alternative 400-Hz three-phase current with rated voltage 200/115V;

- direct current with voltage in rectifying unit’s connection point running parallel with 31,4 … 23V storage battery without voltage interruption.

Electrical potential source of three-phase alternative current is four channels of alternative three-phase current generation system of the carrier plane.

Electrical potential source of direct current is four rectifying units connected to four channels of alternative three-phase current generation system. It is possible to connect to two ground current sources.

The connection of ground three-phase current source is performed with blockage excluding parallel use of ground and on-board sources.

To protect from short circuit and overcharge each electrical circuit has shutdown device .

When one alternative or direct current channel of power supply system breaks, the consumers switch to unfaulty channel. When one rectifying unit breaks, the OSC consumers connected to this channel switch to another rectifying unit.

TV guidance and scanning system performs following tasks:

- external state control of PL when flying to the start-up region, preparing before start and launching PL;

- visual examination of carrier plane and payload separation;

- visual automated, semi-automated and manual guidance of PL after separation from carrier plane (CP) at launch phase within sight with calculation of PL coordinates relative to carrier plane axis;

- real-time displaying of TV-image received from TV cameras and played from magnetic storage devices on the displays of OSC operators;

- recording and storage of TV-images on magnetic storage devices (video recorder).

This systems includes following units, devices and subsystems:

- Side and rear TV-cameras;

- turning platform;

- control console;

- automatic guidance and coordinate measuring systems;

- displays (can use the same from IDS);

- video recorder.

TV cameras provide optical image processing into full TV-signal.

Air- hydraulic system of maim propulsion unit is placed aboard of the carrier plane, belongs to OSC and used for pre-flight and pre-start preparations of the main propulsion unit (MPU), fuel component fueling, emergency oxygen draining at PL launch cancellation and maintenance of fire and explosion safety of PL.

Air-hydraulic system (AHS) of MPU consists of:

- gas supply system for pipelines’ expulsion, booster pumps’ bootstrap, engine cavity’s pre-start expulsion and extra charging of oxidant tank at emergency oxygen draining;

- liquid oxygen draining system at cancellation of main unit starting during flight;

- gas supply system for PL compartments’ expulsion;

- support system for pre-flight preparation of MPU of PL and tank fueling by fuel components and gas containers.

Explosion and fire protection system (AFPS) performs following tasks:

- supporting of continuous automatic control of fire-risk and explosion-risk fuel components’ concentration in PL compartments;

- PL compartments’ expulsion by inert gas before separation from carrier plane when main lines and engine are cooled;

- fire-risk and explosion-risk situation detection in compartments and extinguishing of possible ignition after carrier plane and payload separation.

Explosion and fire protection system (AFPS) consists of gas control facilities, storage and delivery facilities for fire-fighting and phlegmatized materials; AFPS automation providing work control and management as well as interfacing with ACSLPL, IDS, PSP, OCS, OTMS; warning and indication devices.

Explosion and fire protection system (AFPS) provides extinguishing of possible ignition by means of supplying fire-fighting materials inside compartments at warning. Separation system (SS) performs following tasks:

- PL fixation on the carrier plane on all modes of their joint flight;

- electro-pneumohydraulic connection between PL and CP;

- control and transmission of status and ready signals into on-board control system;

- maintenance of PL and CP safe separation at normal launch and in abnormal situations.

Separation system (SS) consists of:

- front and rear power junctions between PL and CP;

- plug-type connections of main lines and electro- pneumohydraulic connections between PL and CP;

- automatic and control devices.

Air thermostatting system (ATS) being part of the on-board starting complex is used for maintenance of given temperature range in non-pressurized compartments, charging and ventilation at ground exploitation and in joint flight with a carrier plane.

The system consists of:

- air-to-air heat exchanger;

- turborefrigerating system;

- dehumidifier;

- air temperature regulator;

- control block with temperature and pressure sensors.

Liquid thermostatting system (LTS) is used for thermostatting of liquid heat carrier of temperature control system.

Liquid thermostatting system (LTS) consists of:

- double-circuit hydraulic system;

- relay ladder logic device;

- microprocessor;

- refrigerating machine with actuating fluid.

OSC’s LTS and ATS management is performed by ACSLPL.

The on-board telemetry measuring system (OTMS) supports data collection from sensors, electronic devices and on-board computers, signal processing, storage and transmission through autonomous or combined radio link, receiving by ground stations (fixed or mobile), registration, information preprocessing and convenient visualization of results.

The system carries out information gathering from ACSLPL, IDS, TGSS, ATS, LTS, SS, PSS, AHS of MPU of OSC.

Taking into account measuring volume, telemetry information consumers, communication channel capacity, communication modes and efficiency requirements, the OTM system are based on the following principles:

- address acquisition of measured data providing redundancy elimination and information re-distribution between data sources;

- flexible programming of acquisition process (parameter sampling frequency alteration and alteration of parameter number) for optimal application of radio link capacity, memory size and joint functioning maintenance with other measuring systems;

- non-synchronou digital stream receiving through multiplex information communication channel (MICC) in accordance with GOST 26765.52-87 standards;

- local principle of data acquisition;

- information acquisition from separating objects by cable connected to detachable connections;

- information transmission by autonomous radio link;

- information transmission by combined radio link;

- information transmission to other measuring systems;

- formation of short messages for transmission (remote signaling);

- management by OSC (ODC) or special console in accordance with matrix commands.

System information density is limited by radio link capacity which allows to transmit only general parameters of OSC systems.

The conclusion

The OSC development was conducted and defended by enterprise labour collective. The results of this work confirmed appropriateness of chosen direction of OSC development for multipurpose aerospace system. Available scientific and technical experience shows that on-board starting complex can be used as a universal facility for launching any orbital or experimental flying vehicles with correspondent characteristics.

The further development phases include creation and adjustment of “OSC crew-OS crew” conception model, including dataware, crews’ interaction and their safety.