- Documentation

- Table of contents

- AKC

- Introduction

- Airframe Creation

- Technological Problems

- Experimental plant

- Building plant

- Conf. Development

- Aerodynamic Designing

- Algorithms of control

- Guidance & control

- Stand for training

- Training center

- Horizontal flight tests

- Crew on board

- Auto Landing complex

- Structure

- Payload bay

- Metallic material

- Non metallic material

- Non metallic material

- Cabin assembly

- Thermal designing

- Thermal protection

- Heat protection

- Quartz fibre

- Computer designing

- Gas's dynamic

- Strength

- Basic direction

- Tech. preparation

- Technical diagnostics

- Methods & means

- Radio nav. support

- Information & controls

- Control of onboard equ.

- Electric power dist.

- Electromagnetic

- Antennas installation

- Auxiliary power unit

- Hydraulic system

- Cabin

- Safety

- Air transportation

- Automatic landing

- Exp. working out

- Return to space

- SPIRAL

- Analysis of concept

- Horizontal take-off

- BOR-4 & BOR-5

- MAKS multipurpose

- MAKS-D

- Thermal design

- Gas & thermal design

- Wing deflection

- Flight performance

- Maks structure

- Metal materials

- Advanced non metallic

- Information provision

- Onboard starting comp.

- Onboard control comp.

- Control organization

- Aerospace systems

- Economic investigations

- Triplane aircraft

- Technical inventions

- Scientific potential

- Triumph and tragedy

- Birds of a Feather?

- TsAGI wind tunnel

- Bibliography

| -The Mriya is destroyed. |

| -Shipping of Buran-KS to Sotchi. |

| -Antonov is no more. |

| -Buran is now a museum. |

| -New pictures of the blogger Ralph Mirebs. |

BURAN Orbital

Spaceship Airframe

Creation

Specificity of Organization of Technological Preparation to BURAN Production

Chernousov V.N.

The main objectives of improvement of organization and the results of technological preparation to BURAN orbital spaceship (Orbiter) production are surveyed. The attempt is made to define further development of technological preparation of airspace and aviation systems production.

Technological preparation to BURAN Orbiter’s production (TPP) has included a wide-scale complex of works on the following main directions (TPP functions). It was development of design technological effectiveness, technological planning, development and adjustment of manufacturing processes, design of technological auxiliaries of optional equipment, means of mechanization, their manufacturing and adjustment, material and labor costs normalization, drawing up technological designs, projects of reconstruction, TPP processes organization and regulation, etc.

Particular composition, contents, complexity and scopes of works on TPP functions, the resources, needed for their accomplishment, depended on design features of BURAN Orbiter and conditions of its production.

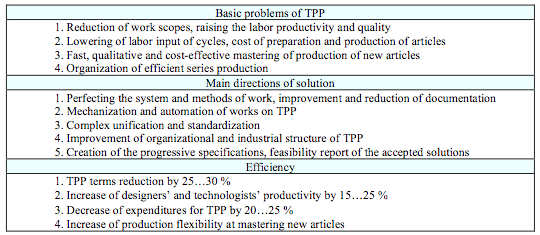

Organization of BURAN Orbiter TPP ensured the accomplishment of a number of tasks, which it envisaged (Fig. 1) at reaching the set technical and economic indices of the basic production (quality and reliability of constructions, their minimum possible labor intensity and cost price, raising of labor productivity of workers, etc.).

BURAN Orbiter’s TPP was carried out with the objective of performing its functions by progressive methods on the basis of scientific principles, which have been worked out by a long-run experience of the branch.

The following refer to the number of such interdependent principles:

- increase of a specific weight of works of technological preparation of production, which are executed beforehand;

- response, greatest possible overlapping of works and parallelism of their fulfillment;

- flexibility and succession of production at change of articles;

- complete set and system approach to fulfillment of works;

- specialization and cooperation;

- reasonable centralization of works, etc.

Indicated and other principles anticipated wide-scale application of previously designed standard solutions on all functions and at all stages of TPP, correlation of activities and directions of TPP organization at its consideration as a unified large system.

The following referred to the number of main interdependent directions of improvement of BURAN Orbiter TPP organization (Tab. 1), which originated from the indicated principles and integrated by the branch system (Fig. 1):

1. Perfecting systems and methods of works on TPP functions and TPP as a whole at regulation and reduction of the used documentation and document circulation. This direction pursued the purposes of rational ordering and creating conditions for the most effective fulfillment of works at elimination of their duplication, and reduction of unnecessary scopes of works and labor input.

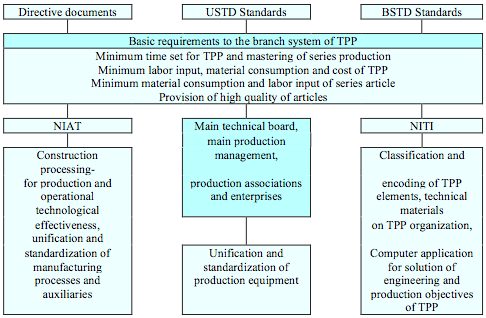

Regulation and reduction of the technical documentation were based on the following standards:

- of State Standards of the Unified System of Technical Documentation (USTD) in case, when they could be applied without change;

- Standards of the Branch System (BSTD), when the specificity of BURAN Orbiter production requires addition or change in documents referred to USTD;

- Standards of Enterprises (STD), complementary to the USTD and BSTD standards according to the enterprise specificity.

|

|

|

Figure 1. Block diagram of the branch system of technological preparation to production |

Improvement of the system and methods of works accomplishment were of great importance all the more so, because only in these conditions, mechanization and, especially, automation of technical-engineer and administrative works on TPP became effective and generally possible.

2. Mechanization and automation of technical-engineer and administrative works is one of principal objectives of TPP improvement. This objective affected a wide range of issues from application of the elementary means of office equipment to use of computers in the complex with modern means.

Computers were used for technical-engineer and administrative works.

In this direction wide-scale works were accomplished of computer-aided programming of machining heat-protective coatings.

3. Complex unification and standardization of production process elements (constructions, technologies, auxiliaries, equipment, elements of production process) formed the basis for problem solving of reduction of terms, scope and cost of preparation of production.

The quality of manufacturing process, auxiliaries, articles was refined, the organizational-technological level of BURAN Orbiter production was increased and its cost price – reduced. The major works on unification and standardization at BURAN Orbiter production had the new qualitative contents. The attention was focused on standardization of operations groups, creation of technological modules and systems of auxiliaries.

The level of manufacturing process classification was increased by 20%, of standardization of auxiliaries - by 10…15%, of special-purpose equipment - by 20%.

4. Improvement of organizational and industrial structure of technological services.

Complexity and diversity of works on technological preparation of BURAN Orbiter production have demanded the precise organization of technical services, since the structure and number of workers at plants-contractors were different. The critical organizational questions of formation of production preparation bodies were decided on the basis of standard structures and number of control board, designed at NIIAT.

|

|

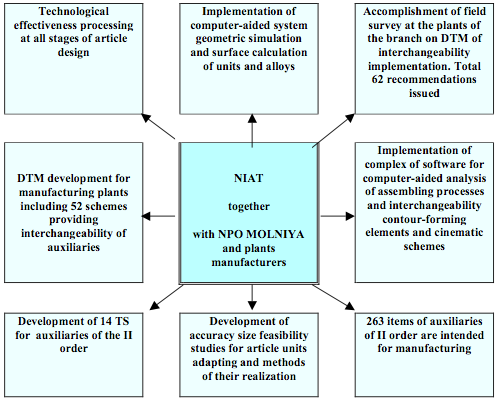

Figure 2. Maintenance of interchangeability at BURAN Orbiter creation |

At that the line was conducted to strengthening the production preparation management, the greatest possible centralization of its functions, elimination of works by functions duplication, strengthening of a number of perspective divisions, precise specialization of TPP workshops.

5. Creation and application of advanced norms and feasibility study report of the received solutions served the objective base for planning, acceleration and costs reduction of works on TPP.

The enlarged and differentiated norms of labor input and design cycles of manufacturing processes, equipment, metal consumption of auxiliaries and a number of others were referred to the number of such norms.

The block diagram of technological preparation of BURAN Orbiter production took into account the correlation of branch and inter-branch managing documents, basic requirements of BSTD, inter-institute links, regulations from the part of the Ministry and enterprises-manufacturers.

All this has permitted to ensure not only straight line, but also feedback connection between the enterprises and organizations, participating in activities on TPP, and provided for operative solution of arising problems of BURAN Orbiter production.

High labor intensity of BURAN Orbiter creation has demanded the organization of wide-scale inter-branch cooperation not inherent to aviation, which in its turn, arose a problem of interchangeability and linkage (Fig. 2).

As a rule, all aircraft manufacturing plants have the specific features of interchangeability support. At production of BURAN Orbiter the interchangeability was maintained by implementation of the computer-aided system of geometrical simulation and surface calculation, using the complex of software for the computer-aided analysis of assembly processes and interchangeability of contour-forming elements and cinematic schemes.

|

|

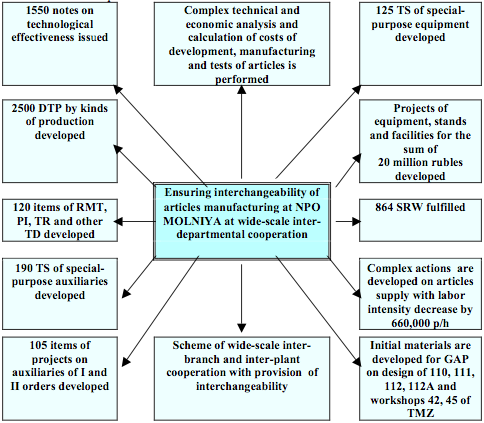

Figure 3. Technological support for BURAN creation |

Much work was accomplished on technological preparation to BURAN Orbiter production (Fig. 3).

It was required to construct and to upgrade the existing departments for production preparation, to equip them with new kinds of metal-working and blank-producing equipment.

A lot of equipment, both stockpile and moulds were manufactured in cooperation.

The organization of BURAN Orbiter TPP allowed:

- to reduce TPP terms by 25…30%;

- to increase designers’ and technologists’ productivity by 15…25%;

- to reduce costs of TPP implementation by 20…25%. The experience of BURAN Orbiter TPP organization has a high practical value and may be used in many respects at creation and production of aerospace systems of the future, and of other flying vehicles and will allow to achieve an essential increase of technical and economic indices of production. Further development of works on aerospace systems TPP will be connected to solution of the following basic problems: classification and encoding of technical and economic information during TPP;

- establishment of unified methods of TPP;

- development of normative-technical base of TPP;

- creation of an information search system of TPP;

- development of computer-aided systems of design of manufacturing processes and auxiliaries.